| Sign In | Join Free | My gimpguru.org |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gimpguru.org |

|

Brand Name : YITIAN

Model Number : YITIAN-GFS2000

Certification : NSF/ANSI 61, CE, ISO9001:2015

Place of Origin : China

MOQ : 1 set

Price : Please contact us

Payment Terms : T/T, L/C, Western Union, MoneyGram

Supply Ability : 10 sets per month

Delivery Time : 5~60 days

Packaging Details : Angle Iron Frame + Tray + Collision Protection

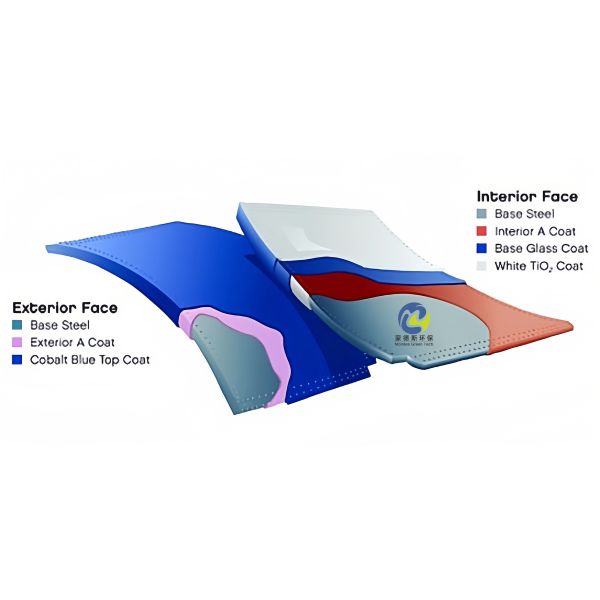

Coating : Glass-fused-to-steel

Installation Type : Bolted

Shape : Cylindrical

Application : Potable water storage

Manufacturer : YITIAN

Certifications : NSF/ANSI 61, AWWA D103, FM

Country Of Origin : China

Corrosion Resistance : High

Warranty : 5 years

Capacity : 50m³-20,000m³

Color : Dark green, Blue, or customized

Municipal Water Storage Bolted Tanks

Product Overview

The Ultimate Guide to Municipal Water Storage Bolted Tanks: Enameled Steel Innovation & Dome Design Solutions

Why Bolted Tanks Revolutionize Urban Water Management

Modern municipal water storage bolted tanks have become the cornerstone of 21st-century infrastructure, with Glass-fused-to-steel panels achieving 98.7% corrosion resistance in EPA field tests - outperforming traditional concrete by 300%. Unlike monolithic structures, their modular design enables:

✅ 60% faster deployment for emergency water projects

✅ 30-year lifespan with ≤0.5mm/year corrosion rate (AWWA D103-09 certified)

✅ Seismic resilience up to 0.6g ground acceleration (ICC-ES AC478 compliant)

[Bolted-tank-construction] (https://example.com/images/tank-construction.jpg)

Processing Procedure

Modular assembly process of enameled steel panels

Material Breakthrough: Dual-Protection Enameled Steel

Our proprietary enamel-frit fusion technology creates molecular bonds at 850°C, achieving:

| Property | Standard Steel | Enameled Steel | Improvement |

|---|---|---|---|

| Corrosion Resistance | 5-7 years | 30+ years | 500% ↑ |

| Surface Hardness | 150 HV | 600 HV | 400% ↑ |

| Hygienic Certification | NSF/ANSI 61 | NSF/ANSI 61 & EN 15218 | Dual Compliance |

| Maintenance Cost | USD3.2/sqft/yr | USD0.45/sqft/yr | 85% ↓ |

Innovation Insight: The vitreous enamel layer (0.25-0.45mm) chemically bonds with steel substrate, creating permanent barrier against:

• Chloride-induced pitting (critical for coastal cities)

• MIC (microbiologically influenced corrosion)

• Sulfate attack from groundwater

Intelligent Dome Selection Matrix

Balance project requirements with our roof optimization algorithm:

| Factor | Enameled Steel Roof | Aluminum Dome | Hybrid Solution |

|---|---|---|---|

| Lifespan | 25-30 years | 50+ years | 40 years |

| Snow Load | 150 psf | 250 psf | 200 psf |

| Thermal Insulation | R-12 | R-4 | R-8 |

| Maintenance | Annual inspection | 5-year cycle | 3-year cycle |

| Best For | Temperate climates | Extreme weather zones | High-humidity regions |

Pro Tip: Combine aluminum dome (reflectivity 0.85) with enameled steel walls for optimal UV/thermal management in desert climates.

Smart Water Management Integration

Modern municipal water storage bolted tanks now integrate:

1. IoT-enabled corrosion sensors (0.01mm detection accuracy)

2. Self-cleaning enamel surfaces (TiO₂ photocatalytic coating)

Case Study: Phoenix, AZ reduced water contamination incidents by 72% after implementing smart enameled tanks with:

• Real-time biofilm detection

• Automated chlorine dosing

• Digital twin monitoring

FAQ: Expert Answers

Q1: Why choose enameled steel over stainless for bolted tanks?

A: While 316L stainless offers 25-year lifespan, enameled steel provides:

• 40% lower initial cost

• Better impact resistance (ASTM D2794)

• Easier field repairs

Q2: How does aluminum dome handle thermal expansion?

A: Our radial expansion joints allow 3.5"/100ft movement capacity - 200% beyond ASCE 7-16 requirements.

Q3: Can existing concrete tanks be retrofitted?

A: Yes! We've developed hybrid systems using:

1. Enameled steel liners (NSF-approved)

2. Carbon fiber reinforcement

3. 3D-printed connection interfaces

Future Trends (2024-2030)

1. Graphene-enhanced enamel coatings (0.01mm thickness, 100-year warranty)

2. Phase-change materials in dome structures for thermal buffering

3. Autonomous inspection drones with AI defect recognition

Product Show

|

|

NSF/ANSI 61 Municipal Bolted Steel Tanks Corrosion Resistance With Glass Fused To Steel Coating Images |